Cast Iron 鑄鐵分析 選配模組

| Image-Pro 影像分析軟體 | MA-Pro 金相分析軟體 | 金相材料分析應用介紹 | 金相分析相關國際標準規範 |

應用介紹

INTRODUCTION >> Sphericity | MA-Pro

鑄鐵(Cast Iron)中的碳(C)含量超過2%以上,主要構成元素為鐵(Fe)、碳(C)和矽(Si),比碳鋼含有更多錳(Mn)、硫(S)、磷(P)等雜質的多元鐵碳合金,有時為了改善鑄鐵的機械性質或物理化學性能,也會添加一定量的合金元素,得到合金鑄鐵。鑄鐵的熔點較低具有良好的流動性以及可鑄性、故易於鑄造成型且好加工,材料也具備抵抗形變、耐磨和減震特性,是良好的工程材料,常做為高震動與高磨耗的機械部件、大型設備基座以及汽車元件等產品的鑄造原料。鑄鐵中的元素除了鐵(Fe)以外,主要元素還有有碳(C)和矽(Si),碳(C)的重量百分比在1.8% ~ 4%,矽(Si)的重量百分比在 1% ~ 3%,若鐵碳合金中碳(C)的含量低於1.8%,一般就會稱為鋼。鑄鐵中的碳(C)主要以石墨(Graphite)的相存在,石墨是鑄鐵中的缺陷,石墨的數量、大小、形狀和分布均對材料的性能存在較大影響。

鑄鐵根據石墨形態(Graphite Morphology)不同,可分為:

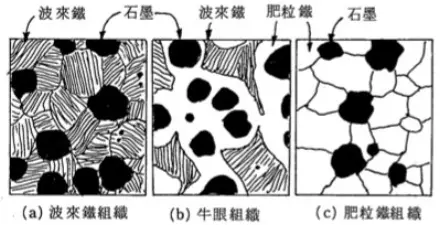

灰口鑄鐵(Grey Cast Iron):灰口鑄鐵的構成元素鐵(Fe),其主要是以波來鐵(Pearlite)的基地組織型態呈現,碳(C)存在於薄片狀的石墨當中,大量的片狀石墨(Flake Graphite)破壞了波來鐵 (Pearlite)的連續性,造成灰口鑄鐵的強度不佳;但是因為在薄片狀介面上的滑動磨擦現象,使灰口鑄鐵有很好的材料阻尼特性,在結構吸振上比一般的鋼跟球墨鑄鐵來得好。

可鍛鑄鐵(Malleable Cast Iron):由一定成分的白口鑄鐵(White Cast Iron)經石墨化退火(2~9天)獲得的,石墨呈團絮狀,可塑性比灰口鑄鐵高。依金相組織的不同,可再分為黑心可鍛鑄鐵、波來鐵可鍛鑄鐵和白心可鍛鑄鐵。

球墨鑄鐵(Nodular Graphite Cast Iron,又稱球狀石墨鑄鐵):將白口鑄鐵(White Cast Iron)改良基地組織與石墨組織型態,經過球化和孕育處理後得到的高性能高級鑄鐵,析出的石墨呈球狀故稱為球墨鑄鐵。近年來,加工廠會將鑄鐵融液中添加鎂(Mg)或鎂合金做為球化劑,再以矽(Si)為接種劑得到球狀碳,可適當調節鑄鐵的基地組織成為波來鐵(Pearlite)或肥粒鐵(Ferrite),得到塑性和韌性與鋼相同的鑄件,故球墨鑄鐵又稱延性鑄鐵(Ductile Cast Iron)。

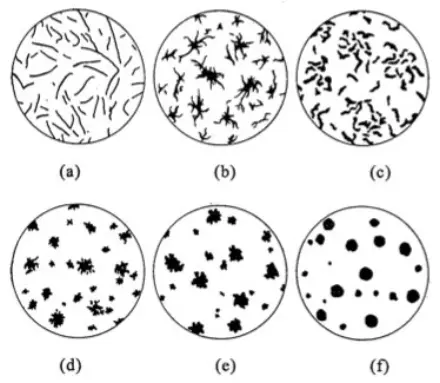

縮墨鑄鐵(Compacted Graphite Iron,又稱蠕墨鑄鐵):其石墨型態呈蠕蟲狀(Vermicular),又名蠕蟲狀石墨鑄鐵(Vermicular Graphite Iron),機械性質及物理性質都介於灰口鑄鐵與球墨鑄鐵(又名延性鑄鐵)之間。在1962年國際鑄件技術委員會所制定的石墨型態中,如下圖,(a) 是普通的片狀石墨(Flake Graphite),(b) 是球化劑過剩時容易出現的末端呈尖狀之石墨,(c) 是球化劑不足時所出現的末端呈現圓形之擬片狀或蠕蟲狀(Vermicular)的石墨,(d) 是出現在黑心展性鑄鐵的塊狀石墨,(e) 是球狀石墨略為崩潰者,(f) 是完全的球狀石墨。圖(c)、(d)、(e)都屬縮墨鑄鐵的型態。

MA-Pro金相分析軟體所選配的鑄鐵分析模組功能,導入影像分析技術將機器學習方法應用於鑄鐵材料的石墨型態分析,針對片狀石墨、球狀石墨與縮狀石墨,提供準確的石墨型態量化功能,可計算平均石墨含量百分比、石墨數量、累計量測面積、片狀石墨長度、球狀石墨球化率,球墨分佈密度(數量比值&面積比值)、縮墨分佈密度(數量比值&面積比值)、平均球墨徑、平均形狀因素計算、石墨尺寸分佈統計等多種計算與統計結果。可再依照ASTM A247、ISO 945、JIS G5502、GB 9441-88和NIK等自動分析計算之標準規範,針對石墨尺寸進行自動分類,分類結果可匯出數據與圖表,並在影像上以色彩將不同分類等級的石墨做標示,亦可讓使用者自訂統計分類等級,滿足特定行業的規範要求,MA-Pro金相分析軟體是科學材料分析與金相分析實驗室必備的一大工程利器。

關鍵字:球化率 Sphericity Spheroidization Rate Percent Sphericity 球墨鑄鐵 灰口鑄鐵 縮墨鑄鐵 片狀石墨 球狀石墨 蠕狀石墨

分析功能

ANALYSIS FEATURES >> Cast Iron | MA-Pro

片狀石墨 / 灰口鑄鐵分析功能介面

Flake Graphite Analysis Function & User Interface

操作界面語系支援英文、繁體中文和簡體中文。

片狀石墨分析

Analysis of Flake Graphite in Grey Cast Iron

灰口鑄鐵是一種常見的鑄鐵,含有大量片狀石墨。該分析功能可自動識別灰口鑄鐵中的片狀石墨,提供高精度的量測與分析結果。

球狀石墨 / 球墨鑄鐵分析功能介面

Nodular Graphite Analysis Function & User Interface

操作界面語系支援英文、繁體中文和簡體中文。

球狀石墨分析

Analysis of Nodular Graphite in Ductile Cast Iron

球狀石墨分析用於評估球墨鑄鐵中球狀石墨的分布與形態,通過影像處理技術對球狀石墨的數量、形狀、大小等進行量測,提供更精確的品質控制與分析數據。

平均石墨含量百分比、累計量測面積計算

球形數量比值、球形面積比值百分比計算

球墨分佈密度計算 - 平均球墨徑 & 平均型狀因素計算

Nodule Size石墨尺寸分佈圖 & 影像色彩分類

蠕狀石墨 / 縮墨鑄鐵分析功能介面

Compacted Graphite Analysis Function & User Interface

操作界面語系支援英文、繁體中文和簡體中文。

縮狀石墨分析

Analysis of Vermicular Graphite in Compacted Cast Iron

縮狀石墨分析用於評估球墨鑄鐵中球狀石墨的分布與形態,通過影像處理技術對球狀石墨的數量、形狀、大小等進行量測,提供更精確的品質控制與分析數據。

球狀條件、片狀條件及過濾條件參數設定 - 平均石墨含量百分比、累計量測面積、縮墨數量計算

縮墨數量比值、縮墨面積比值百分比計算

球墨分佈密度計算 - 縮狀石墨、球狀石墨、片狀石墨面積百分比計算

平均球墨徑 & 平均型狀因素計算 - 縮狀石墨尺寸分佈圖 & 形狀因素分佈圖。

石墨、波來鐵與肥粒鐵含量比例分析功能介面

Area Percentage of Graphite, Ferrite & Pearlite Analysis Function & User Interface

操作界面語系支援英文、繁體中文和簡體中文。

石墨、波來鐵與肥粒鐵含量比例分析

Area Percentage of Graphite, Ferrite & Pearlite Analysis

石墨、肥粒鐵、波來鐵含量百分比計算。